In aviation, the term "slew" refers to the rotation of an aircraft around its vertical axis, which is also known as yawing. This action is essential in the process of steering the aircraft, especially during ground operations such as taxiing or during flight to adjust for wind conditions. The management of slew is crucial for the precise control of the aircraft's orientation and is a fundamental aspect of a pilot's skill set.

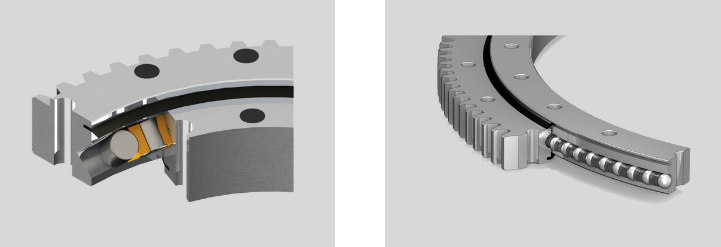

Slew bearings play a pivotal role in the aviation industry, especially in the context of rotary-wing aircraft like helicopters. They are designed to handle a combination of axial and radial loads with a significant moment load. This makes them suitable for applications where a rotational movement is required with a structure supporting a high moment load.

The design of a slew bearing is inherently complex due to the substantial demands placed upon it. It must not only provide smooth and efficient rotation but also support the considerable weight of the aircraft's components, withstand the forces generated during maneuvering, and endure the variable environmental conditions encountered during flight. The ability of a slew bearing to maintain performance under these conditions is a testament to the precision engineering that goes into its manufacturing.

In helicopter applications, the slew bearing is often found in the rotor assembly, where it facilitates the rotation of the blades. This rotation is critical to the aircraft's ability to lift and maneuver. The bearing ensures that the motion is controlled and stable, which is crucial for the safety and reliability of the helicopter's operation.

The engineering behind these bearings involves a selection of materials that can withstand high stress and variable temperatures. Moreover, the geometric design must ensure that the stresses are evenly distributed to avoid any potential points of failure. Advanced lubrication systems are also a key feature of slew bearings, ensuring that they remain operational over long periods and under the demanding conditions of flight.

Maintenance of slew bearings is another essential aspect of aviation operations. Regular inspections are necessary to check for signs of wear or damage. Any issues detected can have serious implications for the safety of the aircraft and must be addressed promptly. Proper maintenance not only ensures the longevity of the bearing but also contributes to the overall safety of the aircraft.

The integration of slew bearings into the design of an aircraft must also take into account the aerodynamic impact. These components must be housed in such a way that they do not adversely affect the aircraft's performance. Engineers must, therefore, design the bearing assemblies to be as compact as possible, without compromising their operational efficiency.

In conclusion, the aviation industry relies on slew bearings to ensure the safe and efficient operation of aircraft. Their role, although often not highlighted, is vital in the control systems of aircraft. The high-quality engineering and rigorous maintenance they require are indicative of their importance. With advancements in materials and design, slew bearings continue to evolve, offering greater performance and reliability for the aviation sector. Their contribution is a cornerstone in the construction and operation of aircraft, underscoring the marvels of modern engineering in aviation.